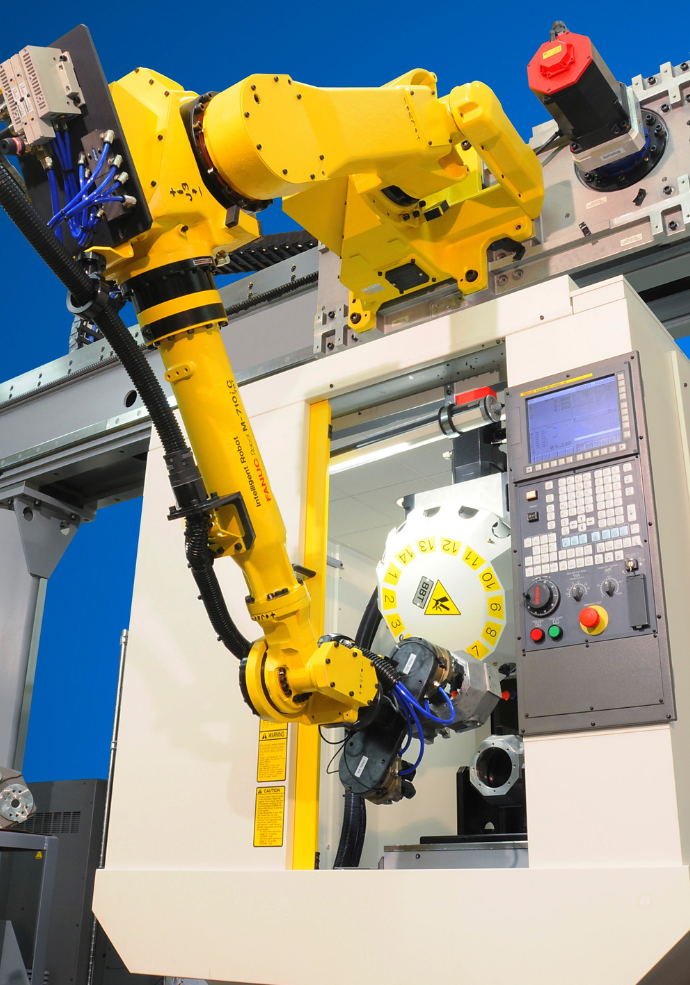

Robotic arms, at the central point of modern manufacturing and production, are changing the rules in a way that was previously not possible. They combine precision, safety and efficiency. These marvels of the mechanical realm – sometimes called robot arms – have been a necessity for industries all over the world, driven by an urgent need to cut operating costs without sacrificing quality. Robotic arms are being integrated into production lines in order to reduce costs and increase safety. We’ll look at how these revolutionary machines reshape the industrial landscape.

Image credit: automatedsolutions.com.au

The primary force behind the global surge in robotic arm adoption is cost efficiency. The demands on factories to cut down production mistakes, material waste and workplace injuries is never-ending. A robotic arm addresses these challenges head-on. Robots are more precise than humans when it comes to performing repetitive tasks, reducing cost and eliminating costly mistakes. For instance, in high-volume industries such as automotive manufacturing arms perform precise welding and part placement to ensure perfect assembly every time. This can lead to substantial savings, as fewer defective products mean less rework or waste.

Security is another pillar of the robot arm revolution. Human workers are at risk in the course of performing a variety of manufacturing tasks, such as handling hazardous material or operating machinery that is heavy. With the help of robot arms, employers can keep employees out of hazardous environments, significantly decreasing the chance of workplace injuries. Robot arms, created as a kinematic ring of flexible joints, mimics capabilities of a human arm but operates without the risk of physical harm. With hand end effectors, these machines can accomplish tasks that could be hazardous for humans, like welding or spinning.

Robotic arms’ versatility can be a game changer in various industries. From assembly for automobiles to electronic production, robotic arms are able to adapt to a broad range of tasks. The programmability of these robot arms allows them to execute complex tasks like painting or applying fiberglass with an unparalleled degree of precision. In warehousing, robotic arms have changed palletizing by automating the process of loading merchandise onto pallets using precision and speed. Automation not only increases efficiency, but also guarantees security, as robot arms can operate tirelessly without fatigue.

The rising popularity of cobots (collaborative robots) that interact with human employees is one of the most exciting developments in this area. Cobots, that are outfitted with robotic arm, can be able to interact with humans in a seamless manner, unlike industrial robots, which are normally restricted to cells. In a factory environment the robot arm of a cobot might handle difficult lifting or repetitive tasks, allowing human workers to focus on more challenging tasks. This type of collaboration boosts efficiency and ensures a secure work environment, as cobots can be programmed to alter or stop their movements when an individual is within.

Robotic arms have a significant impact on modern manufacturing, and not only in terms of safety or efficiency. They are essential to industries that require high accuracy in tasks like welding, assembly or material handling. For automotive production, for example robotic arms can rotate and place components in assembly to ensure perfect alignment, without the need for human involvement. In the field of electronics, robotics are employed to manage delicate components, which decreases damage and increases the quality of output.

As industries continue their evolution, robotic arms’ role will increase. They will be a key element in manufacturing’s future due to their capacity to reduce costs, improve security and adapt to various tasks. Robot arms, which blend cutting-edge technologies with human creativity is not just a tool, but partners in progress. They are the engine behind technological innovation and alter the way in which the world is constructed.